- RESIN 3D PRINTER SLICER SOFTWARE HOW TO

- RESIN 3D PRINTER SLICER SOFTWARE UPGRADE

- RESIN 3D PRINTER SLICER SOFTWARE SOFTWARE

- RESIN 3D PRINTER SLICER SOFTWARE CODE

- RESIN 3D PRINTER SLICER SOFTWARE TRIAL

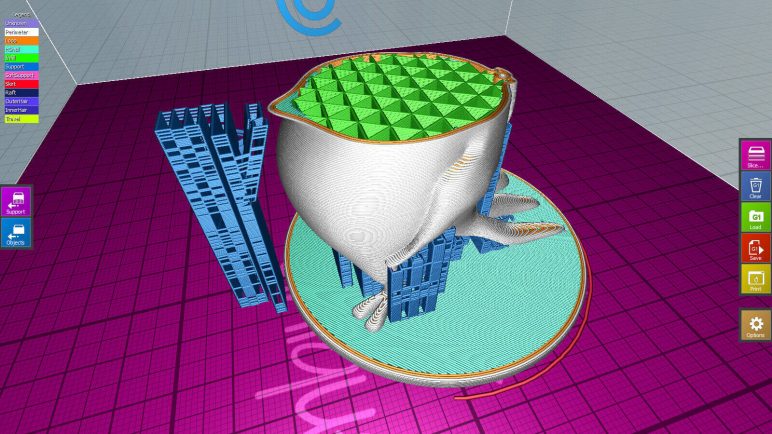

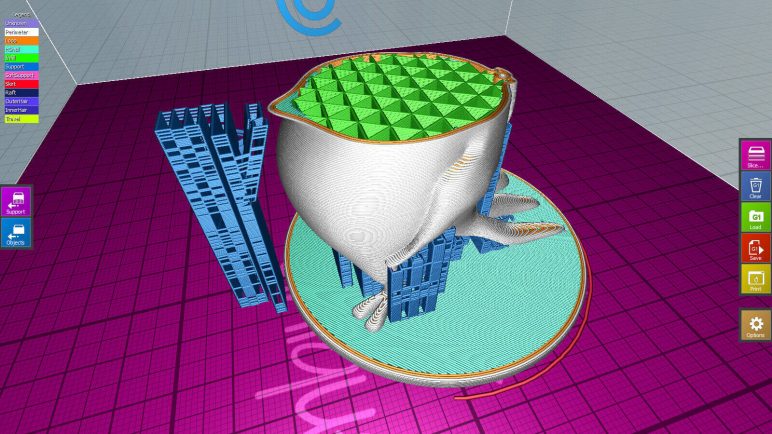

Print quality differs between slicing software.

RESIN 3D PRINTER SLICER SOFTWARE SOFTWARE

Some slicing software has limited file support (e.g.

RESIN 3D PRINTER SLICER SOFTWARE UPGRADE

Some slicing software has a free version but you have to upgrade to unlock certain features. Slicing software can underestimate and overestimate print times. Which slicing software is best for you depends on your level of experience. KISSlicer is a good choice for domed surfaces. Simplif圓D and Slic3r are also very, very good. Looking at what people recommend on forums, the top-rated free slicers are Cura, Simplif圓D and Slic3r.Ĭura is free and it is an excellent fully-featured slicer. What slicing tool is best for 3D printing? If this happens, we recommend you try a new slicer. For instance, sometimes a slice file will crash a program or it won’t export to G-code. It’s also important to note that some slicing programs work better with certain 3D printer manufacturers. RESIN 3D PRINTER SLICER SOFTWARE TRIAL

You can download some of the above software for a free trial before purchasing your printer to see the features and learn how it works. These companies have their own software or have partnered with a third-party, open-source software. It’s important to note that we are a partner to Markforged, Formlabs, 3DGence, Ultimaker, Builder Extreme and Essentium.

Simplif圓D (Builder Extreme & Essentium). Here’s a list of some of the most respected slicing software programs: However, unless explicitly noted, you are actually free to choose whichever slicing software you like – so feel free to test plenty out! Some 3D printer manufacturers, such as Ultimaker and Markforged, ship their 3D printers with slicing software in the box (Cura and Eiger). They range in price from free to thousands of pounds. Now, there are several hundred slicing programs out there to choose from. Whichever way you feel about slicing software and its relationship with 3D printing, the fact is this – you need it to get the job done. Now that you know what slicing software is, let’s take a look at some options. Hobbyists can use basic slicing software but professional applications might call for something more advanced. With this, it is possible to not only create slicer information about the geometry of a part but to create information about that part’s design intent so that the finished part is suitable for longer-term end-use. More advanced slicing programs also take into account GD&T (Geometric Dimensioning and Tolerancing). These paths are instructions for geometry, and they tell a 3D printer what speed to print at for various points and what layer thicknesses to adopt, if applicable (sometimes it is best to do this manually). Slicing software in more detailīasic slicing software – in fact, all slicing software – will create paths for a 3D printer to follow when printing. For most people, it’s best just to use slicing software. If you want to learn G-code, there are tutorials online.

RESIN 3D PRINTER SLICER SOFTWARE HOW TO

It isn’t worth your time writing these manually, even if you know how to do it. With a 3D print, it contains hundreds and sometimes thousands of instructions. You see, G-code is an extensive language.

RESIN 3D PRINTER SLICER SOFTWARE CODE

If you know G-code, you could do it yourself, but the code would be hundreds of pages long. G-code is automatically generated by slicing software.

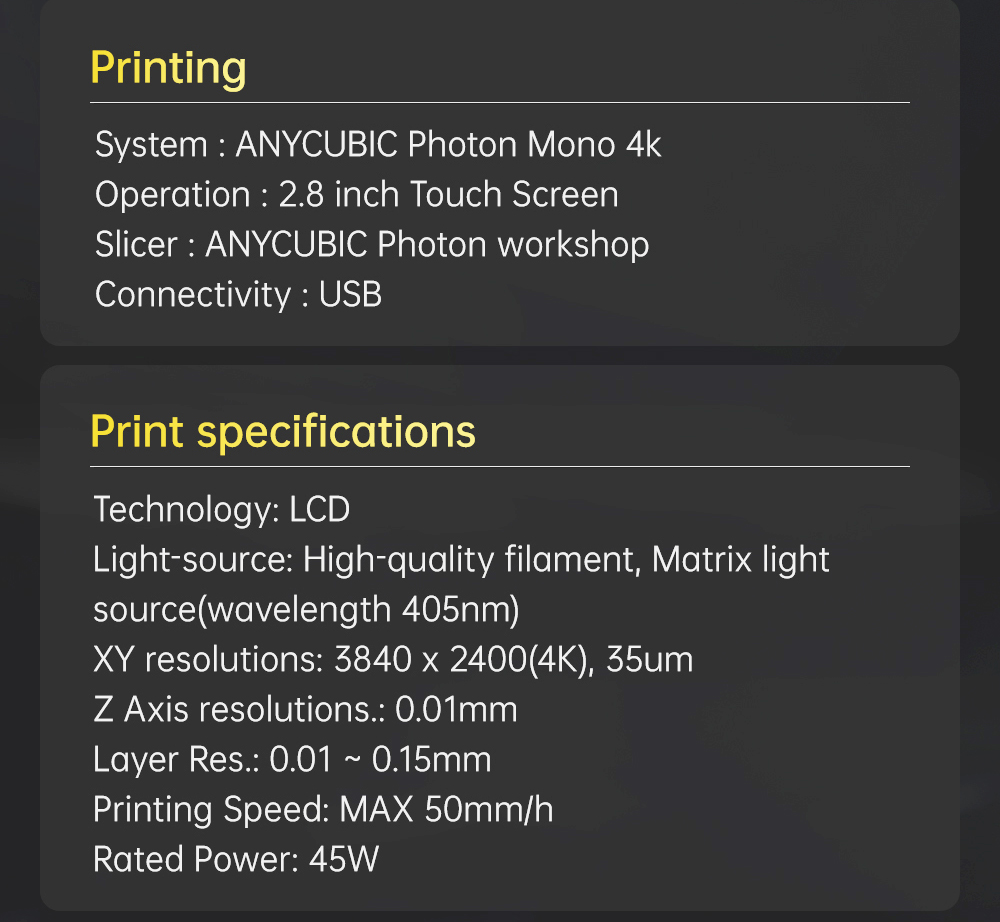

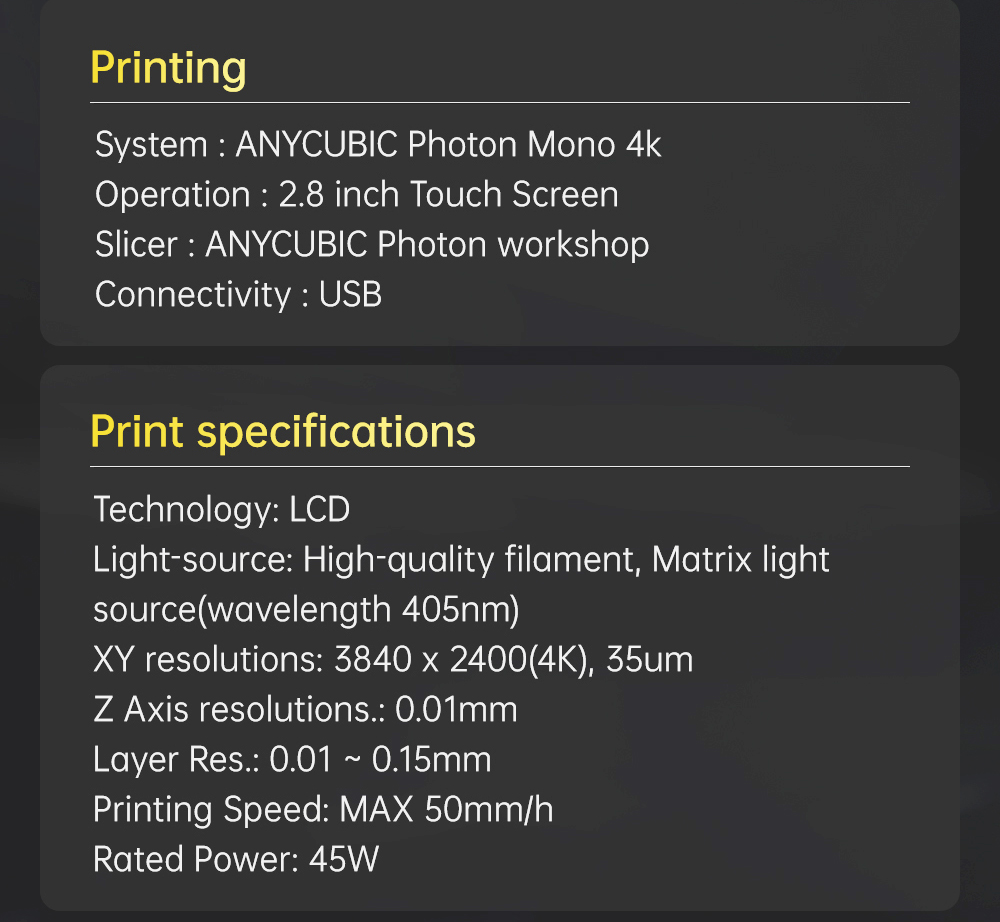

3D printers need the specifications of the object you design to be translated into a language that they can interpret. Slicing software is a necessary element of 3D printing, because 3D printers cannot translate a CAD drawing by themselves. In other words, G-code tells the 3D printer how to print the model. G-codes contain instructions for the 3D printer. If you want a slightly more technical explanation, slicing turns digital 3D models into G-codes (a generic name for a control language) that a 3D printer can understand.

Slicing a 3D drawing translates the 3D drawing into a language that a 3D printer can understand and print. For that, you need dedicated slicing software. Next up, that CAD drawing you have created needs to be sliced. It is with this software you will create your object to the specifications you require. When it comes to 3D printing an object, a few things have to happen.įirst of all, you have to design the object you would like to print using CAD software, otherwise known as 3D modelling software.

0 kommentar(er)

0 kommentar(er)